Alcon Industries – The Experts In Alloy Castings

Rely on Alcon’s experience and innovation to build and deliver the products you need.

Request a Quote

Our Trusted Partners

Quality Products Made By The Right People With the Right Tools

Alcon Industries is home to experienced engineers, craftsmen, and technicians proficient in imagining, reproducing, and manufacturing the quality products you need. Our foundry has been home to America’s leading producer of heat- and corrosion-resistant alloy castings for nearly a half century, whether it is stock items produced in bulk or specialty units needed at a specific quantity. Alcon manufacturing brings your product to life.

Sand Castings

Our sand casting process offers excellent flexibility to accomplish complex shapes with undercuts or thin walls without requiring extra tooling. This allows parts that are intricately designed, durable, and resistant.

Investment Castings

Learn more about our investment casting process, where we craft intricate metal parts with expert accuracy and fine finishes. Our experienced staff, working with our state-of-the-art induction furnaces, are only limited by your imagination.

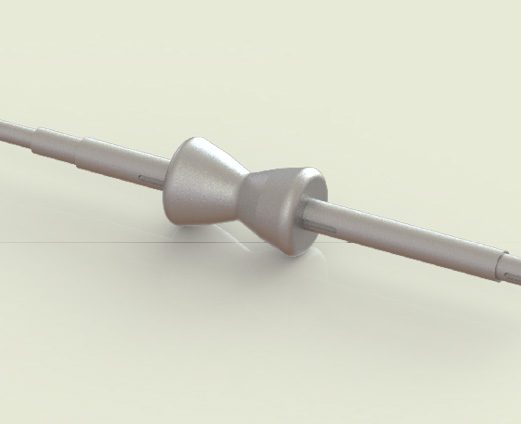

Centrifugal Castings

We design and shape the molds you need to fill any job. Put your trust in our components to fit your machinery by limiting pores and ensuring integrity.

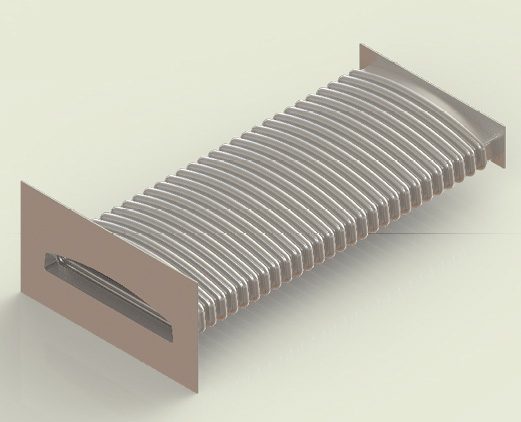

Fabrications

Whether you are looking for radiant tubes, wire baskets, muffles, retorts, trays, or any other type of fabrication, our expert craftsmen deliver top-quality products of any size, shape and quantity. Rely on us for the technical skill and creativity you are looking for.

Furnace Parts

Work with our in-house designer and choose from between a wide selection of alloys to get the parts you need in any quantity. Whether building something from scratch or reverse-engineering, our engineers and technicians can fill any order.

Custom Products

Have you got something unique? Our engineers love a good puzzle. They will work with you to fill any need, size, or quantity.

Our Services Are Second To None

Maximize your time and money by trusting Alcon Industries with your project. Our experienced staff can create, repair, or replace the parts you need to move any job forward.

Custom Design & Engineering

Our engineers have decades of experience in crafting and producing components that are shipped to clients around the world. Combining their skill with precision tools and a limitless imagination, our foundry is home to craftsmen who create the products you envision.

Learn More

Casting & Fabrication

Starting from an existing part, design blueprints, or even a conversation about what you need, Alcon can produce and reproduce anything. Our casting and fabrication process expedites the job and gets the products in your hands.

Learn More

Scrap Recycling Program

Every bit counts! We'll help you stretch your budget. Put your scrap to use and save money on your next order with Alcon through our Alloy Buy Back Program.

Learn More

Alcon’s Team Is Built To Deliver

From our home in Cleveland, Ohio, Alcon Industries has a rich history of providing quality products around the world.

Driven by innovation and customer satisfaction, our manufacturing processes, engineer support, quality assurance, testing, and logistics ensure that the right part gets in the right hands to do the job.

Learn more about us and our leadership.

Learn About Us

Read Alcon’s latest blogs for the latest news and innovations

Furnace Parts Manufacturing: Alcon’s Approach to Quality and Precision

Introduction In the demanding world of industrial furnace operations, component failure isn’t just an inconvenience. It’s a critical disruption that can halt production, compromise product quality, and impact your bottom line. At Alcon Industries, we understand that furnace parts must withstand extreme temperatures, corrosive atmospheres, and continuous thermal cycling while maintaining dimensional stability and structural integrity. Our approach to furnace

Read More

Centrifugal Casting: How Alcon Industries Engineers Superior Machinery Components Through Advanced Mold Design

Introduction Centrifugal casting represents one of the most reliable methods for producing high-integrity metal components with minimal defects. This specialized casting technique uses centrifugal force to distribute molten metal into a rotating mold, creating dense, uniform parts essential for critical machinery applications. At Alcon Industries, we’ve refined this process through innovative mold design techniques that virtually eliminate porosity, delivering components

Read More

Alcon Welcomes New Vice President of Operations

Alcon Industries is thrilled to announce Kevin Vadini joining Alcon as our Vice President of Operations. With over 20 years of experience in aerospace manufacturing, operations leadership, and cross-functional team management, Kevin brings a proven track record of driving process improvements, enhancing production efficiency, and leading large-scale operational teams. His deep expertise in lean manufacturing, quality systems, and strategic planning

Read More